scia Systems

We are proud partner of scia Systems - developer and manufacturer of high-end equipment for ultra-precise surface processing using advanced ion beam and plasma technologies

scia Systems - From Nano to Infinity

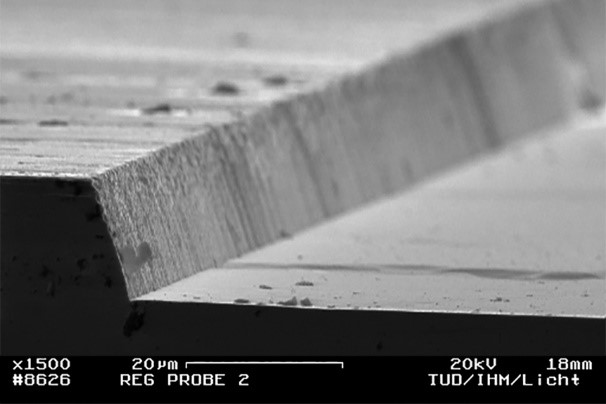

scia Systems, based in Chemnitz, Germany, develops and manufactures high-end equipment for ultra-precise surface processing using advanced ion beam and plasma technologies. The systems are designed for coating, etching, and cleaning with nanometer accuracy.

scia Systems stands for perfection at the nanometer scale. Since its foundation in 2013, scia Systems has established itself as a technology leader in thin-film processing. The equipment is known for its reliability, flexibility, and performance, tailored to the specific needs of industry and research.

Products

scia Systems offers a wide range of ion beam and plasma process equipment that enables our customers to design new and innovative products with unique functional properties. Machines made by scia Systems have been successfully implemented in various high-tech industries worldwide, including microelectronics, MEMS, and precision optics industries.

- scia Trim 200 (Link)

- scia Mill 200 (Link)

- scia Coat 200 (Link)

- scia Magna series (Link)

- scia Eva 200 (Link)

In addition to stand-alone systems, scia Systems also offers customized cluster solutions. Thanks to the scia Clusters’ flexibility, you can choose whether you want multiple chambers dedicated to one process for the highest throughput or combine different process technologies for the highest flexibility in process development and R&D.

- scia Cluster 200 (Link)

Benefits

- Custom-tailored process solutions in a compact and modular system design

- Highest throughput with maximum precision

- In-house technology and process development

- Global sales and service network

- The key components are developed and manufactured by scia Systems itself

Applications

- Electronic manufacturing:

Coating | Etching | Cleaning for MEMS (Link) - Solutions for the optics industry with

ion beam and plasma technologies (Link) - Application Notes for Sensors and other fields (Link)

Technologies